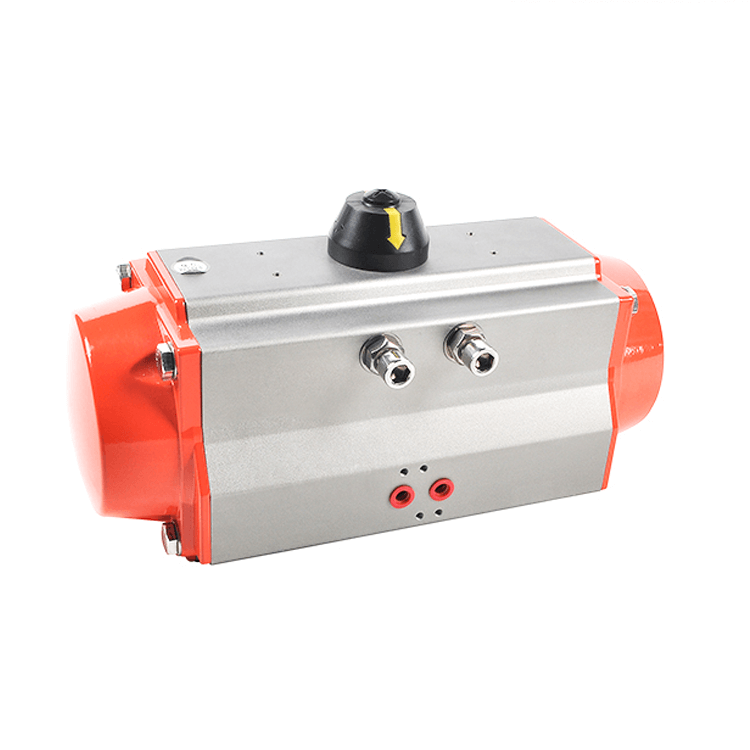

COVNA Series Double Acting Pneumatic Valve Actuator

If you are looking for a double acting pneumatic valve actuator, you are in the right place here. COVNA have manufacturedouble acting pneumatic valve actuator over 20 years. Offering cost-effective actuation solution for water treatment, water filter, shipbuilding, etc.

If you have any demand for double acting pneumatic valve actuator or wanna get a free actuator solution, please contact us sales@covnavalve.com

Double Acting Pneumatic Valve Actuator

Features of double-acting pneumatic valve actuator include eco-friendly, responsive, easy to install and repair, long service lifetime, ISO5211 direct mounting for ball and butterfly valve for actuation solution.

| Actuator Type | Double Acting Pneumatic Valve Actuator |

| Air Supply Pressure | 2.5 bar to 8 bar |

| Torque Range | 8.0Nm to 4678Nm |

| Environment Temperature | -20℃ to 80℃ |

| Actuator Body | Aluminum Alloy |

| Mounting | ISO5211 |

| Rotation | 90 Degrees |

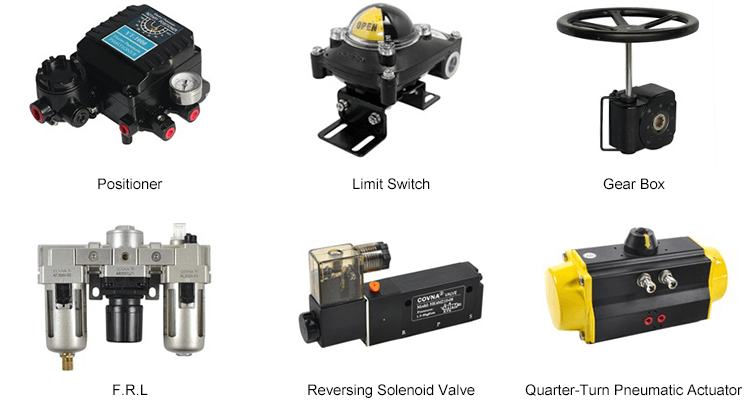

COVNA Pneumatic Accessories

We also provide Positioner, Limit Switch, F.R.L, Pneumatic Solenoid Valve and Gearbox to help your automation easier.

Advantages Of COVNA Double Acting Pneumatic Valve Actuator

1. ISO5211 mounting for ball valve and butterfly valve

1. ISO5211 mounting for ball valve and butterfly valve

2. Air to open and air close. High output torque up to 4678Nm

3. Quality twin rack piston structure. Long cycle life

4. Indicator for convenient checking the switch angle

5. Rack and pinion structure pneumatic actuator

1. High tensile epoxy coated spring sets

1. High tensile epoxy coated spring sets

2. Direct mounted solenoid connections according to NAMUR standards.

3. The position indicator is designed to remain on the actuator for continuous indication when limit switch is not being used.

4. Base drilling, for valve mounting, and center, according to ISO 5211/DIN 3337 standards.